End Condensation Woes: The Ultimate Nano Waterproof Coating Solution for Smart Locks

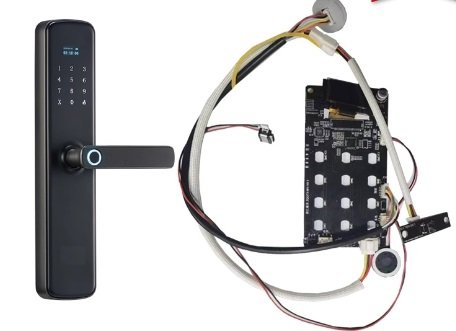

In the harsh winters of northern regions, smart locks frequently develop condensation due to drastic temperature fluctuations after indoor heating activates. This not only triggers recurring short circuits and malfunctions but also significantly increases maintenance costs. Understanding condensation causes and implementing effective anti-condensation technology has become critical for enhancing smart lock reliability. Superhydrophobic Nano Coating is a professional circuit board protection solution engineered for this challenge, delivering efficient and long-lasting moisture protection.

Why Does Condensation Plague Smart Locks?

Exposure to significant temperature differentials is the root cause:

- Temperature Gradient:Warm, humid indoor air contacts the cold lock surface, causing water vapor to condense into droplets. This intensifies with indoor heating during winter.

- High Humidity:When ambient humidity exceeds 50%, increased vapor saturation leads to easier condensation on cold lock surfaces. Dehumidifiers can help mitigate this issue.

- Dust Accumulation:Dust particles on surfaces (e.g., displays) attract and hold moisture, creating nucleation sites that worsen condensation. Regular cleaning reduces this effect.

Condensation: The Silent Killer of Smart Locks

Intrusive condensation causes severe internal damage:

- Skyrocketing Short-Circuit Risk: Moisture-induced shorts cause system failures, escalating repair costs and after-sales pressure.

- Component Corrosion & Degradation: Prolonged water exposure oxidizes and corrodes circuit boards and electronics, drastically shortening lifespan.

- Impaired Performance & Failure: Moisture disrupts precision sensors and components, leading to reduced functionality or malfunctions.

- Critical Safety Hazards: Lock failures or short circuits can prevent emergency access, directly threatening household security.

Core Objectives of Anti-Condensation Protection

The fundamental goal is complete isolation of electronics from moisture and vapor to ensure:

- Stable, failure-free smart lock operation

- Significantly extended device lifespan

- Enhanced safety and reliability

- Consistent, worry-free user experience

Key Properties of the Ideal Protective Material

Effective anti-condensation coatings must possess:

- Exceptional Barrier Properties:Seal out moisture contact with PCBs to prevent short circuits.

- Superhydrophobicity:Water droplets instantly slide off the coated surface, minimizing condensation adhesion.

- Superior Oxidation Resistance:Inhibit metal corrosion from oxygen/humidity, ensuring long-term stability.

- Excellent Insulation:Block surface currents to eliminate short-circuit risks and component interference.

The Optimal Solution: Chaofang PC-4 Superhydrophobic Nano Coating

PC-4, a cutting-edge nano-coating technology developed in China, provides comprehensive protection, perfectly solving smart lock condensation issues:

- Superhydrophobic Performance (CA≈160°):Water droplets cannot adhere, creating a perfect “lotus effect” barrier against vapor intrusion.

- Anti-Frost/Condensation Properties:Unique nanostructure grants ultra-high anti-condensation Gibbs free energy, significantly suppressing dew formation.

- Top-Tier Protection:Achieves IP68rating (complete dustproof & continuous immersion protection) and Salt Spray Resistance > 200 hours, thriving in harsh environments.

- Safe & Simple Application:Odorless formula complies with EU RoHS, PFAS, REACH certifications. Applicable via dip or spray coating, touch-dry in 20 seconds at room temperature – extremely user-friendly.