Superhydrophobic:Materials,Properties,Processes, and Applications

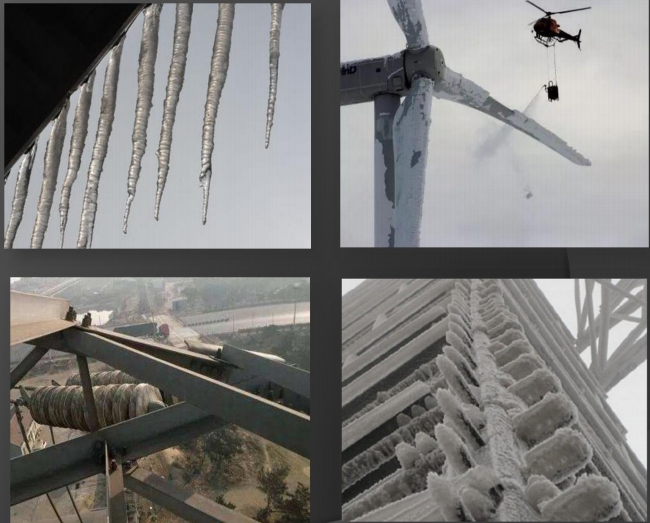

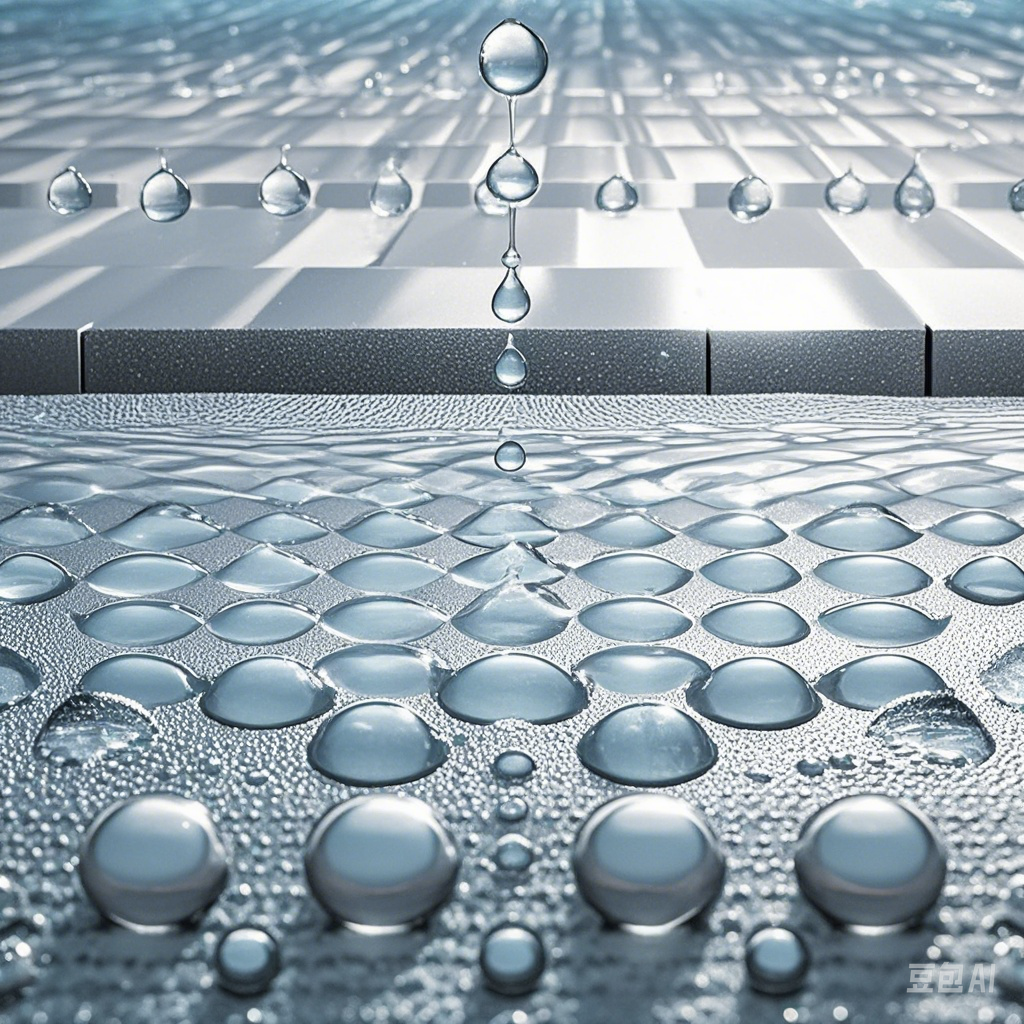

Superhydrophobic materials represent a new class of material with broad applicability in various fields, including ice-prevention technology, where silicon-based superhydrophobic coatings exhibit significant environmental adaptability. Experiments have shown that silicon-based superhydrophobic coatings can actively inhibit and mitigate the formation and growth of ice on power transmission lines. In particular, superhydrophobic coatings delay the freezing of water droplets on coated surfaces, resulting in a significantly lower ice adhesion strength than on standard surfaces. Factors affecting the anti-icing properties of superhydrophobic coatings include surface chemical composition, surface structure, and environmental factors. Achieving effective superhydrophobic surfaces with simple processes is crucial for promoting the application of these coatings. Analyzing the anti-icing mechanism of superhydrophobic surfaces reveals that these coatings have great potential for ice prevention through structural control that accommodates various environmental factors, such as temperature.

Applications of Silicon-Based Superhydrophobic Coatings

Silicon-based superhydrophobic coatings are widely applicable across multiple fields, including radar, 5G base stations, power grids, insulators, bridges, and cables, providing comprehensive anti-icing protection for surfaces on facilities and equipment.

Problems Addressed

- Anti-Icing and Frost Prevention: Effectively suppresses and alleviates the coverage of ice and snow on facilities and equipment, improving operational efficiency and safety.

- Self-Cleaning: Superhydrophobic-coated surfaces quickly remove dirt and dust via rolling water droplets, keeping surfaces clean and reducing maintenance costs.

- Rain Attenuation: Keeps surfaces dry in adverse weather, extending equipment life.

- Freeze Delay: Delays the freezing of water droplets on surfaces, effectively preventing ice formation.

Features

- Superhydrophobicity: Features extremely low surface energy and high hydrophobicity, with water droplets forming a spherical shape on the surface, enabling self-cleaning and anti-icing capabilities.

- Environmental Adaptability: Adapts to various climates and environmental conditions, maintaining stable anti-icing effects.

- Simple Surface Processes: Easy to apply through coating or spraying methods.

Through in-depth analysis of the anti-icing mechanism of superhydrophobic surfaces, ongoing research optimizes coating chemistry and structure to ensure peak anti-icing performance under various environmental conditions.

Application Effects and Features

- Power Grids and Transmission Lines: Silicon-based superhydrophobic coatings can be applied to power grids and transmission lines, effectively inhibiting ice and frost formation, protecting equipment from snow and ice, ensuring reliable operation, and enhancing the safety and stability of the power system.

- Roads and Bridges: On roads and bridges, silicon-based superhydrophobic coatings effectively prevent ice formation, reducing traffic accidents and enhancing the safety and longevity of infrastructure.

- Radar and 5G Base Stations: For equipment like radome covers on radar and 5G base stations, silicon-based superhydrophobic coatings prevent water accumulation and protect antennas and equipment from ice and snow, enhancing stability and longevity.

- Insulators and Cables: Applying superhydrophobic coatings to insulators and cables prevents ice and snow from affecting insulation performance, supporting the stability of power systems.

- Wind Power Equipment: Superhydrophobic coatings on wind power equipment prevent ice buildup on blades and surfaces, reducing the impact of ice on equipment, improving power generation efficiency, and extending equipment life.

Overall, silicon-based superhydrophobic coatings, as an advanced anti-icing technology, offer broad application prospects and significant socioeconomic value. They play an essential role in ensuring the normal operation of facilities and equipment, boosting productivity, and improving safety.

Preparation Methods

As superhydrophobic/superoleophilic materials gain traction in oil-water separation, researchers have identified that the intrinsic oleophilicity of these materials can lead to membrane pore clogging and generally poor reusability, short lifespans, and weak mechanical properties. As a result, scientists are exploring various methods—such as hydrothermal methods, sol-gel, etching, electrospinning, coating, self-assembly, and deposition—to develop superhydrophobic/superoleophilic membrane materials with enhanced stability and multifunctionality (e.g., demulsification).

- Hydrothermal Method: Also known as the high-pressure solution method, it involves using high-temperature, high-pressure aqueous solutions to dissolve typically insoluble substances and create multi-level rough surfaces. This method produces nanomaterials with favorable orientation, uniform doping, reduced reaction temperatures, and controlled results.

- Sol-Gel Method: The sol-gel process involves hydrolysis and condensation reactions of precursors in liquid conditions, forming transparent sol that gradually gelates, followed by subsequent treatment to obtain the desired phase. This method enables controlled reaction conditions, easy operation, and high sample uniformity.

- Etching: Physical or chemical etching techniques, such as laser, chemical, plasma, and photolithographic etching, are used to form micro-nano structures on surfaces. Although precise, etching is costly and economically inefficient.

- Electrospinning: Under an electric field, polymer solutions or melts are sprayed and solidified into fibers, typically suited for polymers. Electrospinning produces fibers with high specific surface areas and porous structures, yielding superhydrophobic membranes with high filtration efficiency and low-pressure drops.

- Coating: A quick and simple way to achieve different surface textures, including spray, dip, brush, and electrophoretic deposition methods. Spray coating uses a spray gun to deposit particles onto substrates, forming rough textures; dip coating immerses substrates in active solutions; brushing applies coating directly, while electrophoretic deposition suits water-based coatings.

- Self-Assembly: Mimicking natural molecular self-assembly, this technique constructs functional material surfaces at the molecular level, with controllable particle size, good dispersion, and easy operation, albeit requiring precise condition control.

- Deposition: A low-cost, effective method to create multi-level micro-nano textures, including chemical and electrochemical deposition. Chemical deposition forms micro-nano structures through surface reactions, while electrochemical deposition uses cathodic reduction and anodic oxidation to build surface structures.

Superhydrophobic/superoleophilic materials prepared using these techniques on diverse materials (such as degradable silk fibroin, polydopamine, tannic acid, synthetic fibers, and mineral particles) effectively separate water-in-oil emulsions or heavy oil/water mixtures. However, they face challenges in separating light oil/water and water-in-oil emulsions. Additionally, many current methods are complex, costly, and unsuitable for large-scale production.

Future Prospects of Superhydrophobic Materials

Superhydrophobic materials, known for corrosion resistance, self-cleaning, and anti-icing properties, have vast potential across fields such as metal, textile, wood, and biomedical applications. Despite these advances, superhydrophobic materials reveal shortcomings, primarily due to the micro/nano structures that limit direct surface contact, increasing local pressure and making them prone to wear. This drawback underlines the need to improve material stability and durability.

Current production faces challenges like stringent preparation conditions, complex techniques, prolonged processes, and inconsistent hydrophobic effects, hindering widespread commercial use. Moving forward, developing low-cost, environmentally friendly superhydrophobic materials with scalable production methods will address the increasing industrial demand for functional superhydrophobic solutions. In the near future, superhydrophobic materials based on sustainable, eco-friendly resources will likely dominate the market, fully meeting the needs of society and end-users.